Durable Master Bond high performance fire resistant adhesives, void fillers are engineered to meet safety, weight management, strength/stiffness, acoustic, aesthetic, maintainability, assembly, cost requirements of aircraft manufacturing corporations. Select compounds pass both vertical and horizontal burn tests under FAR 14 CFR 25.853(a) used for determining fire, smoke, toxicity (FST) compatibility of cabin/cargo compartment components inside aircraft. These non-halogenated formulations are ROHS compliant and do not contain any SVHCs as per REACH standards. Employed for bonding interior panels, lavatory modules, overhead storage bins, floors, doors, galleys these products assure reliable construction of efficient, comfortable, appealing, lightweight aircraft interiors. Additionally unique Master Bond systems have been developed for manufacturing a wide rage of secondary structures including fairings, instrument panels, spoilers and air brakes among others.

Performance Properties of Adhesives for Aircraft Applications

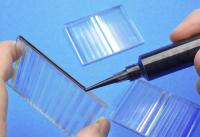

Room/low temperature curing systems cure smoothly, in uniform thicknesses providing a good fit even in tight clearances. They have excellent adhesion to multiple substrates including metals, thermoplastics, composites. Special grades allow additional handling time for proper positioning of wide panels. Insert potting and bracket bonding compositions reduce production costs. Compact manual/pneumatic cartridge dispensers are available to ensure accurate mixing, consistent shot control, minimize waste and to increase assembly speed.

While meeting rigorous interior safety requirements are imperative, it is also important for design engineers to consider temperature/environmental compatibility, style/decor, passenger amenities/furnishings, reduced exterior generated sound, cleanability and color degradation. Adhesive systems must withstand abuse from bumping, pulling, pushing, scuffing, scratching, tearing, fungus, water absorption/wicking, cleaning fluids. Mated surfaces can also be exposed to dust, dirt, mud, passenger foot traffic, trolley loads of food/beverages, staining from red wines, cosmetics, cigarette smoke, catsup, soda. Additionally these products bond well to dissimilar lightweight materials such as polyphenylsulfone, polyethersulfone, glass fiber/carbon fiber composites, polycarbonate, polyetherimide and help improve aircraft fuel efficiency.

Some of Our Most Popular Adhesives for Aircraft Interior Applications

|

EP90FR-V Two part epoxy passes vertical burn test portion of FAR standard 14 CFR 25.853(a) for flame retardancy. Passes Boeing standard BSS 7238, Revision C for low smoke and BSS 7239, Revision A for toxicity. Bonds well to variety of substrates. One to one mix ratio by weight. Moderate viscosity. Serviceable from -60°F to +250°F. Excellent electrical insulator. Non-halogenated system. |

|

EP90FR-HFL Toughened epoxy system complies with FAR standard 14CFR 25.853(a) for flame retardancy. Bonding, sealing, coating, potting compound. Passes horizontal burn test specification. Withstands mechanical shock and vibration. Thermal cycling resistant. Non-halogenated type system. Bonds well to dissimilar substrates. Serviceable from -60°F to +250°F. Impressive electircal insulator. |

|

EP93FRHT Two part epoxy system that passes Airbus specifications for flame resistance, smoke density and toxicity. Bonds well to a variety of substrates including metals, composites, glass, ceramic and many plastics. One to one mix ratio by weight. Moderate viscosity. Service operating temperature range from -80°F to +400°F. Excellent electrical insulator. Non-halogenated system. |