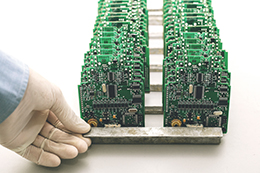

Leading electronic manufacturing services (EMS) companies depend on Master Bond custom adhesive systems for the assembly of electronic products for original equipment manufacturers (OEMs). Application specific formulations are available for low, medium, high volume production operations and are utilized in the following industries:

Leading electronic manufacturing services (EMS) companies depend on Master Bond custom adhesive systems for the assembly of electronic products for original equipment manufacturers (OEMs). Application specific formulations are available for low, medium, high volume production operations and are utilized in the following industries:

- Wearable electronics

- Computer

- Communication

- Automotive

- Aerospace and defense

- Healthcare

- Commercial equipment

- Marine

- Lighting

Original equipment manufacturers outsource the construction of electronic hardware to Tier 1 to Tier 3 suppliers. Master Bond has provided technical support to these EMS companies. Our liquid, paste, film bonding agents have contributed to avoiding subsequent reliability issues, ability to bond dissimilar substrates, sealing against liquids/gases, low temperature processing, gap filling capability, vibration damping properties, minimal shrinkage upon cure, protection from corrosion, thermal stability, and chemical inertness. They also feature fatigue resistance, decrease weight, improve aesthetics, can eliminate stress concentration and will maintain their structural integrity over time.

Master Bond’s line of materials consists of electrically conductive, thermal conductive and electrically insulative products. Particularly noteworthy are the heat dissipative characteristics of adhesives for smaller, miniaturized, tightly packaged circuits. Silver filled systems have an exceedingly low volume resistivity of 10-3 ohm-cm for electrical interconnection. They also exhibit inimitable thermal conductivity.

Other indispensable Master Bond grades are used for:

- Die attachment

- Conformal coatings

- Glob top encapsulants

- Impregnating/insulating coil windings

- Surface mounting technology (SMT)

- Liquid gap fillers

- Underfills

- Heat sink attachment

- Bundle optical fibers

- Biocompatibility

- Ferrite cores and magnets

- UV/visible light curing

- Potting

- IC packaging

- Rapid fixturing

- EMI/RFI shielding

- Alignment of lenses, prisms

- Moisture sensitive sensors

- Static dissipation

- Structural bonding

- Form-in-place gasketing

Master Bond is continuously developing innovative products to meet the evolving needs of this most competitive global market. Our systems have enabled EMS companies to improve efficiency, quality, sustainability, yields, productivity, time to market and safety. Emerging technologies have given new opportunities to boost growth. Master Bond has kept pace with these challenges by providing the best customer service and trying to exceed customer expectations. From the internet of things (IoT), virtual reality, 3D printing, 5G connectivity, electronic vehicles, Master Bond has been at the forefront of helping EMS companies facilitate an increase in market share and profitability.

Master Bond is playing a pivotal role in supplying polymeric compounds for vital electronic requirements for EMS fabricated products. They include:

- Gaming consoles

- LCD TVs

- Handheld devices

- Routers

- Servers

- Tablet computers

- Printers

- Precision optical components

- Automotive electric parts

- Mechanical equipment

- Cable modems

- Surgical assistive devices

- Imaging systems

- Robots

- Sensing equipment

- Flexible PCBs

- Industrial control panels

- Digital communication products

- Medical diagnostic devices

- ATMs

- Network security equipment

- Toys

- Automotive infotainment

- Small appliances

- Auto navigation systems

- Smart meters

- Automated test equipment

- Autonomous guided vehicles

- Power switching equipment